September 2010

Stickers for Buildings: Monitoring Environmental Impact

Cars Have Mileage Ratings - Why Don't Buildings Have the Same for Carbon Emissions?

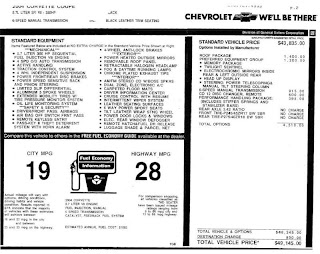

It is hard to believe, but there is a lot to learn from the automobile industry in terms of environmentsl efficiency. One model, in particular, is how car dealerships display stickers on each car stating its fuel consumption.

These stickers effectively communicate, and help control, the overall fuel consumption and the carbon emissions in all cars. The U.S. government was able to double new car uel efficiency between 1975 and 1985. These results eventually lead to President Obama's decision, in May 2009, to continue raising the average for cars and light trucks. By 2016, the estimated savings are expected to be 900 million metric tons of carbon, the equivalent of closing 194 coal-fired power generators.

What about Our Buildings?

What is preventing us from replicating this and applying it to our buildins? Buildings are responsible for about 40 percent of total carbon emission in North America, while SUVs are responsible for only three percent. Imagine the difference we could make by placing efficiency stickers on buildings and decreasing their emissions by 50 percent over a 10 year span. In only one year, a 50 percewnt reduction of building emissions could save 1.14 billion tons of carbon in the U.S.

There is no general standard for building performance and there are challenges when it comes to tracking energy efficiency of our buildings. City and government authorities do not have visibility into the "fleet average" performance of their buildings. Lack of information prevents the implementation of a policy to minimize building carbon emissions using the same procedure as seen with automobiles.

Change is really possible. Emerging technologies provide appropriate tools to perform measurements and calculations of carbon emissions, water usage and total energy usage. By introducing these measurement capabilities, we can evaluate each building's performance and assign an efficiency sticker. When a city has acquired all measurements for its buildings, an average can be calculated in footprint per square meter of floor space.

Imagine that a city averages 50 kilograms of carbon per square meter, but government regulations under jurisdiction must achieve a target of under 40 kilograms of carbon per square meter in a five year span. This results in a 20 percent reduction. To reduce the overall footprint, a similar limitation can be placed on water and total consumption.

Comparison Brings Improvements

The U.S. government does not require in-depth information on a city's buildings or specific targets for individual building types. It requires only an overall benchmark of the average footprint (comprised of carbon, water and total energy) and for individual cities to independently determine based on knowledge of building stock.

Residential buildings could be controlled through similar use of a footprint sticker and the benchmark average methodology. If houses provided visible stickers, comparison of carbon ratings and evergy performance could be a determining factor towards buying a house. Neighbors could compare performance with one another, which would help drive change.

Driving Towards Positive Change

We are currently headed in the right direction. President OBama hopes to make all U.S. buildings carbon neutral or with zero emissions by 2030. Other countries like the U.K. now require houses on the market to be nergy rated. By having footpring stickers on buildings, city building stock averages and building emissions are severly lower, and they have created substantial global carbon savings.

Automobile companies have made a huge progress in the reduction of car pollution using measurement stickers and enabling direct comparisons. With the right tools, we can achieve the same improvement of operating efficiency in our buildings as we have with automobiles.

Ron Dembo, Zerofootprint 9/23/10 for Environmental Leader comment on our facebook page

Why is Energy Efficient Lighting Outpacing Lighting Controls in Existing Buildings?

Why are so many building owners implementing projects to improve the efficiency of their lighting without also improving the control of their lighting? At the core of the issue is the reality that lighting controls are very different from energy efficient lighting. The result of this dichotomy in the marketplace, is the under-utilization of lighting controls as a way to drive sustainability, energy savings and financial returns. Lighting control or sensor projects are often 20 to 50 percent smaller than they should be, leaving energy savings opportunities untouched.

Why does this happen? Two primary reasons: 1) Lighting controls and sensors can be complicated and confusing and 2) quantifying the energy savings with accurate empirical data is rarely offered. Although lighting manufacturers have strived to make user-friendly products, lighting controls are much more challenging, so lighting contractors may not offer the option, and building owners often avoid them.

Quantifying energy savings is most likely the single largest barrier to comprehensive lighting control and sensor projects. The challenge of accurately modeling the use of a building in order to calculate energy savings from lighting controls requires not only a thorough understanding of the building space, but also the collection of enough data to be statistically significant. In the absence of this data, service providers become hesitant to present savings with any level of confidence and buyers become hesitant to invest in comprehensive projects.

When lighting controls and sufficient data have been addressed, a comprehensive project can be implemented and the financial returns often outpace those of an energy efficient lighting upgrade.

The fact that the market has relied on service providers to provide technology that they are not qualified to deliver, has led us down a path where each new LED or high performance system that is installed without controls, significantly diminishes our continuing conservation and sustainability efforts. In the final analysis, 'lighting' is not the same as 'lighting controls.'

Brad Jenkins, PES Controls 9/10 comment on our facebook page

Wind Turbines Slated for New York

The Port Authority of New York and New Jersey hopes to have the five wind towers, each more than 280 feet tall, operating on the west side of New York Harbor within three years, while the Department of Veterans Affairs considers wind turbines on or near its hospitals in manhattan and Brooklyn, reports The New York Times.

The five turbines are expected to produce as much as 7.5 megawatts, which the authority plans to use to operate the container port, then feed the surplus energy into the local power grid, offsetting some of the authority's consumption elsewhere, according to the article.

In 2998, New York City Mayor Michael Bloomberg proposed to install wind turbines on top of the city's skyscrapers and bridges, as well as off the coastline of Queens and Brooklyn to help reduce the ciy's dependence on power plants that run on fossil fuels. Currently there are large-scale projects underway and only a few samll turbines on the roof of an apartment building in the Bronx and a wind-powered electronic billboard for Coca-Cola in Times Square.

However, the city's Economic Development Corporation is evaluating the feasibility of putting turvines atop buildings, including a warehouse at the Hunts Point Cooperative Market in the Bronx. There is also an ambitious project underway in partnership with utility companies and the New York Power Authority to build a wind farm on about 65,000 acres of the Atlantic floor, which will generate as much as 700 megawatts of power by 2016. Nearby in the city of Bayonne, MJ, an equally harge turbine as the ones at the port authority will be installed to power a sewage-pumping station.

Touted as the first windmill in New York Harbor, construction of a 262 foot tall turbine has already started at a plant operated by the city's Municipal Utilities Authority. The $5.6-million tower, which would be the biggest wind turbine in New Jersey outside of Atlantic City, will generate more electricity than it needs to power the plant by September.

Stephen J.Gallo, executive director of the utilities authority told The New York TImes the city plans to sell the excess power, saving at least $150,000 a year. Both projects in Bayonne will help New Jersey achieve its goal of developing 200 megawatts of wind evergy onshore by 2020, according to the article. The state's energy plan also calls for 3,000 megawatts of offshore wind energy offshore within 10 years.

The New York Times 8/2010 comment on our facebook page

Color Filter Could Boost LCD Efficiency by 400%

Researchers at the University Of Michigan have created a color filter that could boost the efficiency of LCDs, the power hog of all your gadgets, by more than 400 percent, and no, I didn't add an extra zero there.

The researchers made an optical film that colors and polarizes the light that passes through an LCD, taking the place of the several layers of optical devices that typically serve the same function in an LCD. Those multiple layers give rise to inefficiencies: the best LCDs out today only emit eight percent of the light their backlights produce. The researchers found that the film allowed 36 percent of the light to make it through - a huge increase.

The color filter is made up of three ultra-thin layers--two layers of aluminum enclosing a layer of insulating material--and it only measures 200 manameters thick. The filter is etched with slits that produce different colors when illuminated by the backlight. The slits are matched in scale to the wavelength of visible light and their length and distance apart determine the color produced.

This grating pattern is where the efficiency boost comes in. In current LCDs, a polarizing filter absorbs half the light (the part with the wrong polarization). The grating on the new filter doesn't absorb the light with the wrong polarization, it instead reflects it back towards a mirror that flips some of its polarization, letting more light pass through the filter.

Researchers are trying to improve the efficiency further and are coming up with ways to mass produce the filters, like with roll-to-roll printer.

EcoGeek, by Megan Treacy via MIT Tech Review comment on our facebook page

Does your company have energy-related news to share? Please submit it to info@impactenergysolutions.com and we will publish it in an upcoming Newsletter.

Subscribe to:

Comments (Atom)